From Factory Floor to Finished Product: The Journey of a Rubber Roll

- November 3rd, 2025

- Blog

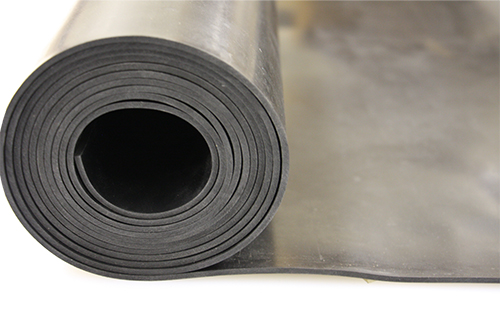

You may look at a rubber roll and see just another industrial material.

At Premlene, we see a story of precision, performance, and partnership. One that begins halfway across the world and ends with a product that helps keep the industries you serve moving.

So what goes into producing that roll of sheet rubber? Let’s follow the journey.

Step 1: Starting with the Right Ingredients

The process begins with selecting the right blend of polymers, fillers, and curing agents. Working with our long-standing production partners we’ve helped engineer compounds that meet the needs of the North American and European markets. Whether it’s oil resistance for Nitrile, weather resistance for EPDM, or high tensile strength for Natural Rubber.

Different rubber types react very differently to temperature, chemicals, and compression, so choosing the right formula here is critical to producing a quality product.

Step 2: Mixing & Milling

The raw materials are mixed in giant mills — kneaded together under high pressure to ensure a consistent, high-quality blend. From here, the material is cooled and cut into sheets, ready to be calendered (rolled out) into a uniform size.

This is where tolerance control matters most. Every roll is engineered to meet exact specifications, from its mechanical properties to thickness, width, and length.

Step 3: Quality Testing

Before it ever gets near a shipping container, each batch goes through testing from tensile strength & elongation to compression set & tear resistance as well as its final dimensions.

Premlene rubber rolls are manufactured in ISO certified facilities, with documentation to back every roll.

Step 4: Packaging & Global Transport

Once tested and approved, the rolls are wrapped, labeled, and loaded. Whether you’re buying a few pallets or a full container, your order is packed to minimize waste, protect quality, and maximize the shipping efficiency.

We manage the logistics, customs, duties and brockerage. Tracking every order from entry to delivery so you can focus on your business.

Step 5: Arrival, Inspection & Application

When your rubber arrives, you’ll have the opportunity to open and inspect it before you make your payment to us. We want to ensure the rubber you ordered is exactly what you received.

Our materials are used in:

- Gaskets and seals

- Vibration damping and isolation

- Padding, insulation, and protective liners

- In countless industrial, automotive, and manufacturing settings

Behind Every Roll Is a Process You Can Trust

From the first compound mixed in Asia to the final product installed in your facility, every Premlene roll is backed by technical data, expert support, and 25 years of experience.

You’re not just buying a material, you’re buying a supply chain, quality system, and a partner that’s invested in your success.

So the next time you roll out a sheet of Premlene rubber, you’re holding the result of a global journey, engineered for performance, and delivered with purpose.

Let’s build your next success story. Reach out to learn more about our products, container load programs, or material selection support.