What’s the Deal with Durometer? Why Rubber Roll Hardness Matters

- December 8th, 2025

- Blog

When it comes to rubber rolls, not all materials are created equal, and one of the most important (but often misunderstood) properties is the durometer.

So, what is durometer? Why does it matter? And how do you choose the right one for your application?

Let’s break it down.

First Things First: What is Durometer?

Durometer refers to the hardness of rubber, specifically how soft or firm it is when you press into it.

Most industrial rubber is measured using the Shore A scale, which ranges from 30A (super soft) to 90A (very hard).

- Low durometer (30A-50A): Think softer, more compressibility, flexible.

- Mid-range (60A-70A): Balanced firmness and flexibility.

- High durometer (80A-90A): Tough, rigid, less compression.

The higher the number, the harder the rubber.

Why It Matters in Real Applications

Choosing the correct durometer ensures that the rubber performs optimally in its intended environment, lasts longer, and provides reliable performance. Using the wrong durometer can lead to premature failure, excessive wear, poor sealing, or even catastrophic system breakdowns, depending on the application.

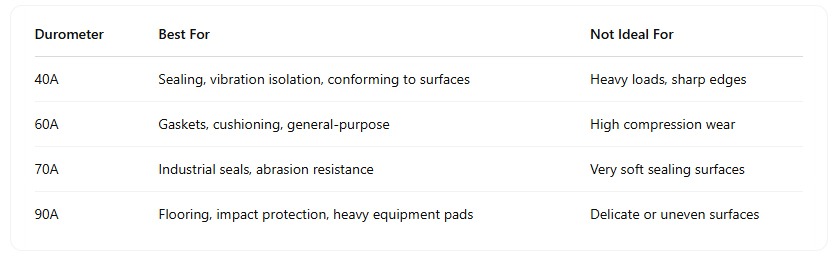

Here’s how durometer impacts performance:

Premlene: Sheet Rubber Rolls in Every Durometer You Need

At Premlene, we stock a wide range of sheet rubber materials in varying durometers, from soft natural rubber to tough-as-nails neoprene and EPDM. Not sure what’s right for you? We’ll help you find the perfect match based on:

- Environment (indoor, outdoor, temperature)

- Chemical exposure (oil, fuel, UV, etc.)

- Pressure, load, and wear factors

Give us a Call

Still not sure what durometer your project calls for? Contact our team or check out our Rubber Characteristics Guide to explore your options.

Because when it comes to rubber rolls, getting the hardness right makes everything easier.